Metallurgical Excellence.

Cryogenic processing not only increases performance in high wear applications, but also provides a complete stress relief process to remove any residual stress that may have been built up in the heat treatment, manufacturing, or machining stages.

Controlled thermal cryogenic processing for extended wear and stress relief of metals offers many advantages:

- Reduces friction and increases wear resistance as well as reducing surface roughness

- Alters and refines the molecular grain structure

- Allows the machining of parts to tighter tolerances

- Increases dimensional stability on critical components

- Relieves stress fracturing

- Provides for easier machining and redressing

- Increases component durability and lifespan

- Lowers replacement costs and downtime due to increased wear and use

What We Do:

Material performance enhancement through Cryogenic Treatment

- Cryogenic separation

- Cryogenic shot blasting

- Cryogenic stator removal of power sections and PCP Pumps

- Cryogenic pipe freezing

- Cryogenic Deflashing Service

- Shrink Fitting Services

- 6 Cryogenic Processors on site, with our largest unit being 32 feet long and 20,000 lb capacity

Please contact us for more information or to receive a customized quote for products or Services.

Ground Engagement Tooling

Millenniums Cryogenic Process reduces costs of tooling including products with hard faced overlays.

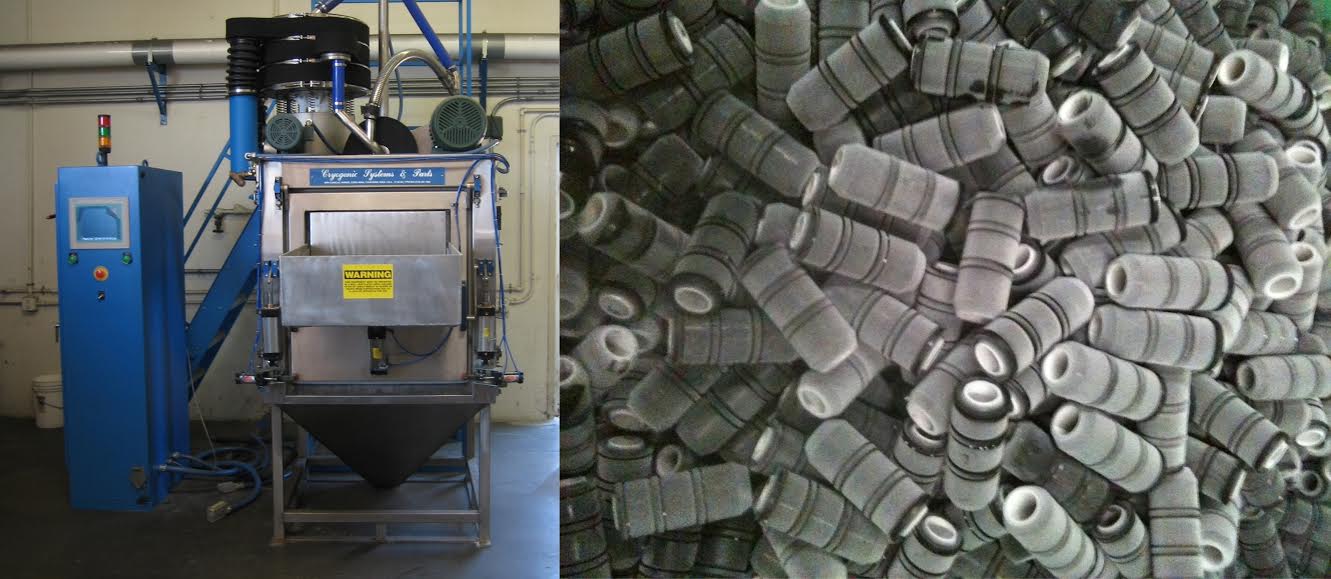

Cryogenic Deflashing Service

Cryogenic high speed shot blast deflashing is a process used by the rubber industry to remove flash from molded rubber parts. The process uses liquid nitrogen, high speed rotation and media (shot blast) in varying combinations to remove the flash in a highly precise, economical and expedient manner. Parts that have thin flash can be quickly and thoroughly cryogenically deflashed. This process is exceptionally good at removing the inner dimensional and complex flash that cannot be removed by any other method.